Ensuring optimal performance and longevity of a syringe labeling machine requires systematic maintenance practices tailored to its specific components and operational demands. Regular upkeep not only prevents unexpected downtime but also enhances labeling precision and efficiency.

Routine Cleaning and Inspection

The foundation of effective maintenance begins with routine cleaning and inspection. After each production run, thoroughly clean the machine’s labeling surfaces, conveyors, and sensors using manufacturer-recommended cleaning agents. Pay special attention to areas prone to adhesive buildup or debris accumulation, as these can impair label adherence and sensor accuracy. Regularly inspect all moving parts for wear and tear, replacing any worn components promptly to prevent operational disruptions.

Calibration and Adjustment

Maintaining label accuracy necessitates periodic calibration of the syringe labeling machine. Verify alignment and positioning of labeling heads, ensuring they adhere to specified tolerances for label placement. Utilize calibration tools provided by the manufacturer to fine-tune settings such as label roll tension and sensor sensitivity. Regularly adjust settings based on label material variations and production conditions to optimize labeling consistency.

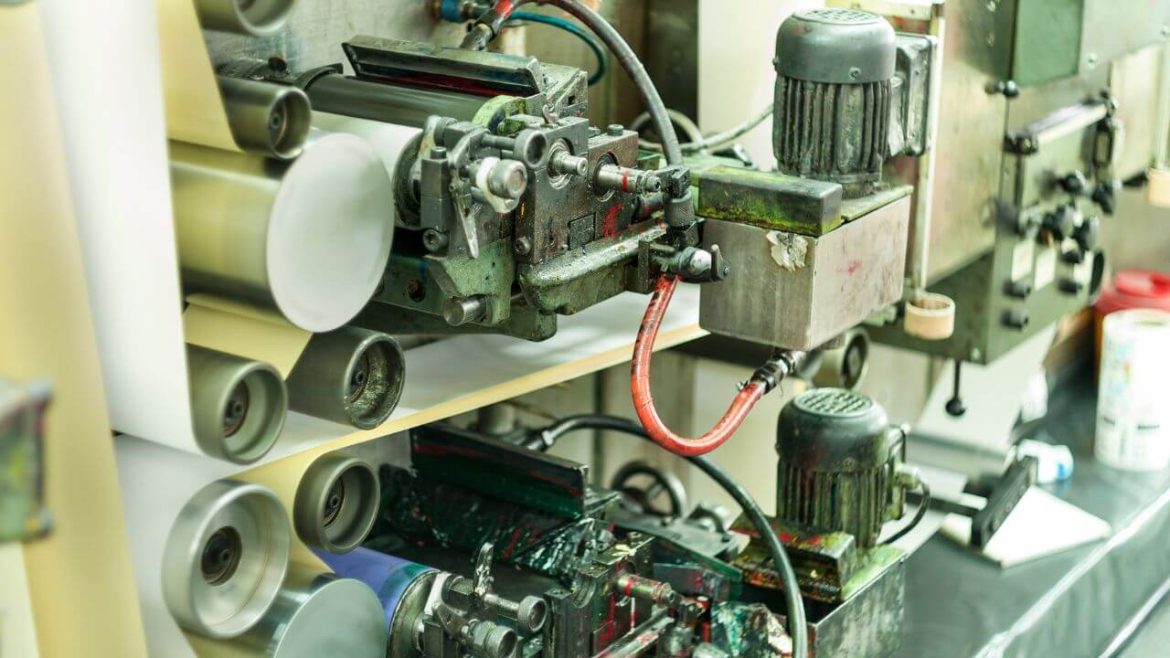

Lubrication and Component Care

Proper lubrication of mechanical components is essential to minimize friction and wear. Follow manufacturer guidelines for lubricant selection and application frequency to ensure smooth operation of conveyor belts, rollers, and rotating parts. Avoid over-lubrication, which can attract dust and debris, compromising machine performance. Additionally, inspect pneumatic systems for leaks and ensure adequate pressure levels to maintain reliable label application and conveyor movement.

Software Updates and System Integration

As technology evolves, staying current with software updates is crucial for maximizing machine functionality and compatibility with evolving labeling requirements. Regularly check for firmware updates provided by the manufacturer, which often include enhancements in user interface, diagnostic capabilities, and integration with production management systems. Ensure seamless communication between the syringe labeling machine and upstream/downstream equipment to maintain uninterrupted workflow and data integrity.

Emergency Preparedness and Troubleshooting

Despite meticulous maintenance, unforeseen issues may arise during operation. Establish an emergency response protocol that includes readily accessible spare parts, troubleshooting guides, and contact information for technical support. Train maintenance personnel in diagnosing common issues such as sensor misalignment, label jams, or motor malfunctions. Implement a systematic approach to troubleshooting, starting with basic checks and progressing to more complex diagnostics if necessary.

Training and Skill Development

Investing in ongoing training for operators and maintenance staff is essential to optimize syringe labeling machine performance. Provide comprehensive training on machine operation, maintenance protocols, and safety practices. Empower personnel to recognize early signs of equipment wear or malfunction and take proactive measures to address them. Foster a culture of continuous improvement where feedback from operators contributes to refining maintenance procedures and enhancing machine reliability.

Documentation and Record-Keeping

Maintain detailed records of maintenance activities, including cleaning schedules, calibration logs, and parts replacement history. Use these records to track machine performance trends, identify recurring issues, and schedule preventative maintenance tasks proactively. Document any modifications or upgrades made to the syringe labeling machine to ensure compliance with regulatory standards and facilitate audits.

Conclusion

Effective maintenance of a syringe labeling machine involves a combination of proactive care, systematic inspections, and skillful troubleshooting. By adhering to established maintenance protocols and leveraging manufacturer support resources, manufacturers can optimize equipment uptime, ensure labeling precision, and extend the operational lifespan of their labeling systems. Continuous improvement in maintenance practices not only safeguards production efficiency but also enhances overall product quality and customer satisfaction in the pharmaceutical and healthcare industries.

3.5