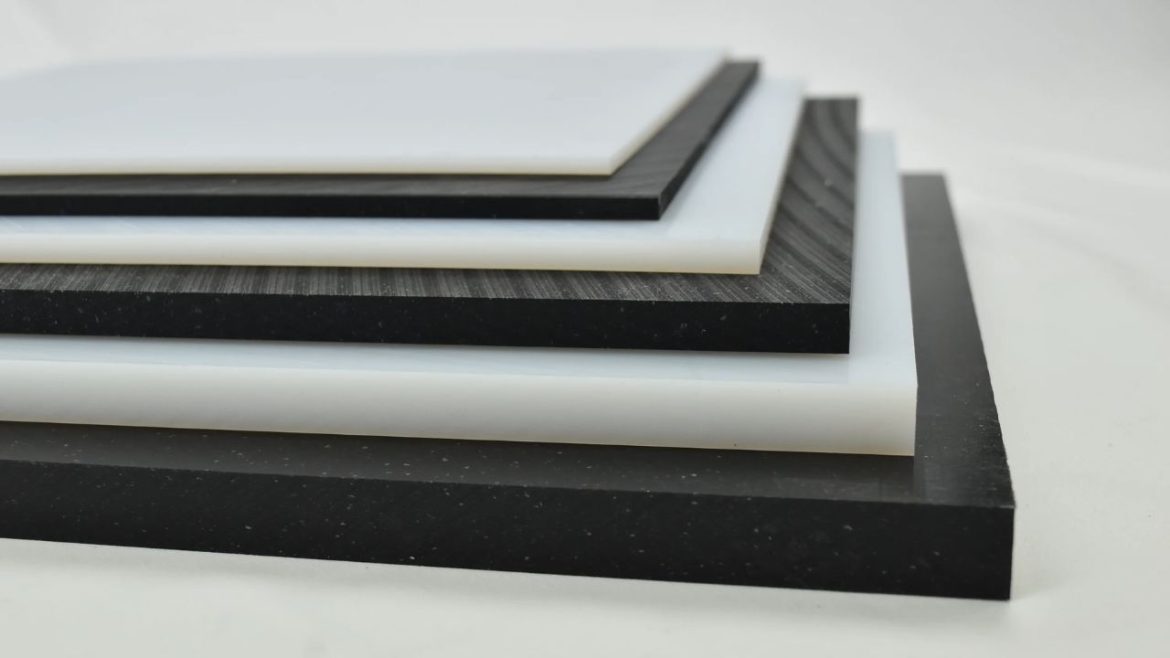

Ultra High Molecular Weight Polyethylene, also referred to as UHMWPE, has become one of the most flexible and high-performance materials in current industrial usage. Among many others, UHMWPE strips have received special interest since they possess a combination of strength, durability, and reduced weight that is distinct in nature. These strips present manufacturers and engineers with a sure way of minimizing wear and tear in equipment, at the same time maintaining efficiency. The increasing usage of uhmwpe strips in any industry highlights the feasibility and flexibility of this material.

Exceptional Strength with Minimal Weight

The high strength-to-weight ratio of UHMWPE strips can be listed as one of the first benefits that the material has. Although the strips are much lighter than the metals or the conventional engineering plastics, they have outstanding impact and abrasion resistance. This makes them suited to those applications where the weight of components is vital and structural integrity is not involved. In the case of industries like material handling, packaging, and transportation, lightweight and strong UHMWPE strips can be used by making the machine work more efficiently, which consumes less energy and minimizes the strain on moving components.

Low-Friction Performance

Besides being stronger, the strips of UHMWPE also have a low coefficient of friction. This property guarantees the easy flow of materials on surfaces and decreases the resistance of mechanical processes. Use of UHMWPE strips in conveyor, chutes, and hoppers also ensures easy flow of material in these systems, eliminating jamming and reducing wear on equipment and the products being transported. Low-friction property also helps to save energy and lessen the maintenance needs because the surfaces covered or lined with UHMWPE are less abraded during the process of time.

Superior Wear and Impact Resistance

The UHMWPE strips are characterized by durability. They are very tough in the wear and impact and are therefore applicable to rough industries. In contrast to metals or traditional plastics that can wear out in the course of constant friction, UHMWPE strips preserve their integrity even when they are used continuously. This durability extends the life of machinery, minimizes manufacturers’ downtime, and minimizes replacement costs. This resistance is particularly beneficial in the areas where heavy materials or abrasive substances are involved, e.g., mining, packaging, food processing, etc, to ensure long life performance and reliability.

Chemical and Moisture Resistance

The second interesting advantage of UHMWPE strips is that they resist many different chemicals and moisture. Such strips will not absorb water, and therefore, they will not swell and vary in size when humid or wet. They are also highly resistant to solvents, acids, and alkalis, and this renders them to a chemically aggressive environment. It is this chemical and moisture resistance that allows UHMWPE strips to be utilized in numerous applications, and these applications are chemical processing, food handling, and the pharmaceutical industries, where hygiene and stability are most important.

Ease of Installation and Handling

The UHMWPE strips are very strong and durable in nature, and most importantly, they are lightweight, making them easy to install and handle. Their portable weight ensures the labor charges are lower, and the setup requires fewer specialized machines. The process of maintenance and replacement is also easier than opposed to heavy materials. Their handling nature, coupled with the properties of operation, makes the use of UHMWPE strips an option to industries that aim to enhance their efficiency in line of operation without necessarily reducing quality.

Versatility Across Industries

The flexibility of UHMWPE strips is reflected by the fact that they have a broad application. Since they were used as wear strips and wear liners in conveyor systems, these strips address the needs of various industries as sealing elements or shields. It is their combination of lightweight, strength, low friction, and chemical resistance that allows them to be customized to either industrial or commercial applications and makes them an invaluable addition to the current manufacturing and material handling solutions.

Conclusion

UHMWPE strips are one of the recent engineering products that are a combination of power, endurance, and weightlessness. Their wear resistance, performance under low friction, impact, resistance to chemicals and water, and easy installation make them an indispensable material in most industries. The manufacturers can use UHMWPE strips in machinery and equipment to enhance efficiency and lower maintenance expenses, and provide long-term performance. The recent invention and use of UHMWPE strips show that they are very important in assisting the running of industries and in addressing the new requirements of high-performance materials.