Efficiency and cost management are paramount determinants of success in the modern manufacturing industry, which is very hectic. By offering integrated, end-to-end manufacturing solutions, ShincoFab helps manufacturers streamline production, reduce lead times, and control overall fabrication costs. The utilization of one-stop sheet metal fabrication services has been used as one of the approaches that has attracted a lot of attention. Contracting many manufacturing processes to one provider allows businesses to simplify operations, cut costs and have better overall project results.

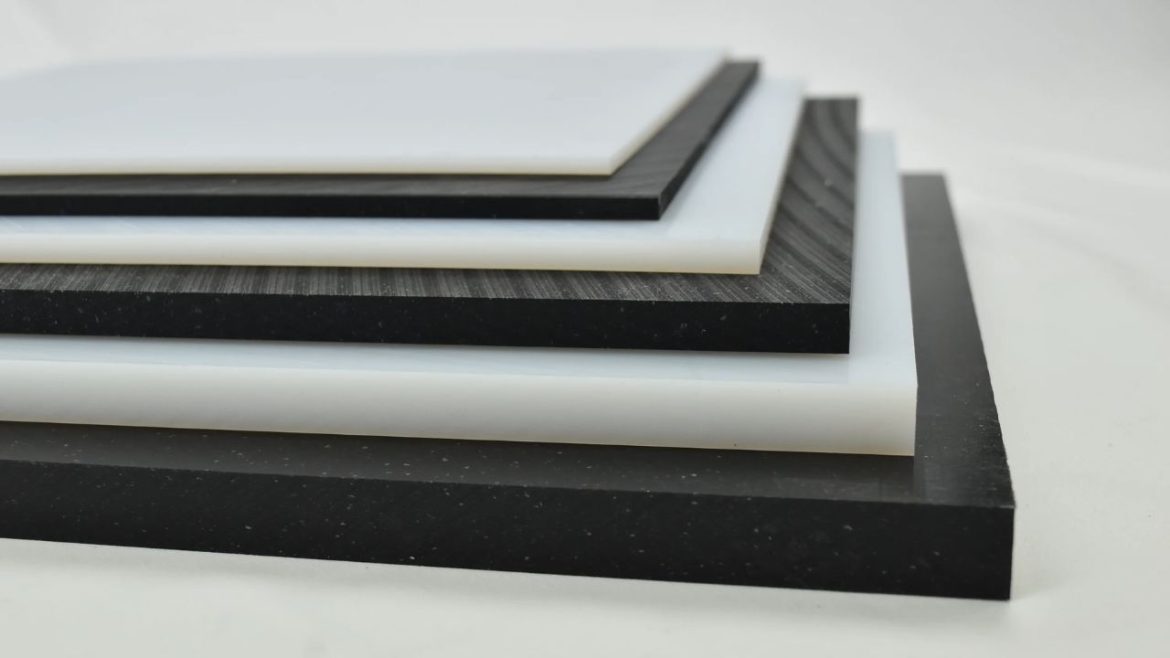

Understanding One-Stop Sheet Metal Fabrication

One-stop sheet metal fabrication is a type of manufacturing process whereby all the processes, including design support to final finishing, are handled by one supplier. This generally involves laser cutting, stamping, bending, welding, finishing surfaces, assembly and inspection. However, rather than deal with several suppliers in the process of various production phases, manufacturers are collaborating with a single supplier that handles the whole production process. Examples of such companies include ShincoFab, which is a company providing end-to-end sheet metal fabrication services to various companies depending on their requirements.

Reduced Lead Times Through Process Integration

Reduction in the lead time is one of the greatest benefits of one-stop fabrication services. In the case of several suppliers, delays are frequent as a result of scheduling problems, transfers between locations, or miscommunication. These inefficiencies are prevented by the single-service provider who incorporates all the processes into a single production system. Materials flow through cutting to forming, welding and finishing without any wastages in terms of waiting times. This combined method makes turnaround times quicker, meaning that products are able to enter the market at a faster rate.

Lower Costs from Simplified Supplier Management

The number of suppliers is also a factor that raises the administrative expenses of procurement, communication, logistics, and quality control. Single supplier overheads will be cut by a One-stop sheet metal fabrication service, where the management of suppliers will be centralized. Having a single contract, contact, and a single quality standard to observe, the companies can considerably reduce administrative and coordination expenses. Also, integrated manufacturers tend to optimize the utilization of materials and production planning, which also lessens wastes and the general costs of manufacturing.

Improved Design Efficiency and Fewer Revisions

A typical cause of escalated costs in sheet metal projects is design inefficiencies. In cases where design, fabrication and finishing are outsourced to other manufacturers, manufacturability challenges could not be detected at an early stage and rework and delays were experienced. At early phases of a project, one-stop providers usually provide Design for Manufacturability feedback and engineering assistance. Designs can be checked prior to the start of production, and before the actual production, problems involving tolerances, bending, or assembly can be addressed earlier at a low cost compared to corrective reworking and wastage of material.

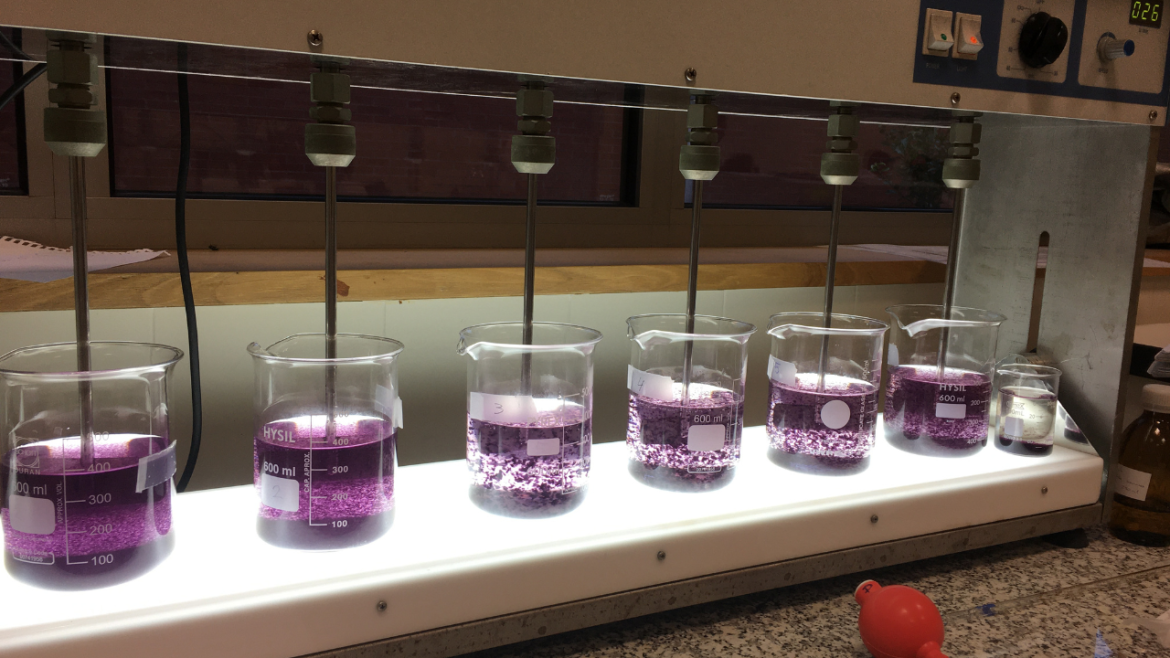

Consistent Quality Across All Processes

When all fabrication processes are handled by a single quality control system, quality consistency is easier to attain. There are several suppliers who might be using other standards, and this raises the chances of having a wrong component or a mismatch in finishing. The one-stop sheet metal manufacturer is a sheet metal manufacturer that implements identical inspection methods in the production cycle and assures that every part is of the same specifications. Indicative of this, ShincoFab, in particular, continues to make quality checks throughout all the processes, starting with the selection of raw materials through to final delivery to the customer, giving confidence in consistent and reliable results.

Optimized Logistics and Reduced Risk

Cost and reliability of delivery are significant in logistics. Moving semi-finished parts from one supplier to another incurs both the expense of transportation and the risks of breakages and losses. One-stop fabrication services reduce the internal logistics by locating the production in a single facility or controlled network. This minimizes risks of handling and provides better protection to the parts, which adds to the cost-saving as well as the integrity of the products.

Scalability from Prototyping to Mass Production

Scalability is another significant advantage of the one-stop sheet metal fabrication services. It is frequently necessary for manufacturers to transition from prototyping to low-volume and finally high-volume production. By dealing with a single supplier during this process, continuity on the tooling, processes, knowledge and standard is maintained. This uniformity aids in the redevelopment, and it ensures an easy transition with the increment in production volumes.

Conclusion

One-stop services are sheet metal fabrications that offer a strategic edge to manufacturers, who are likely to save time and manage expenses without affecting quality. This would simplify the whole manufacturing lifecycle by combining processes, simplifying suppliers, enhancing efficiency in the design and optimizing logistics. Firms such as ShincoFab show how a complete solution of fabrication can enhance quicker manufacturing, reduce costs, and ensure consistent outputs, and in this context, one-stop services are turning out to be a useful option in contemporary production in the industry.