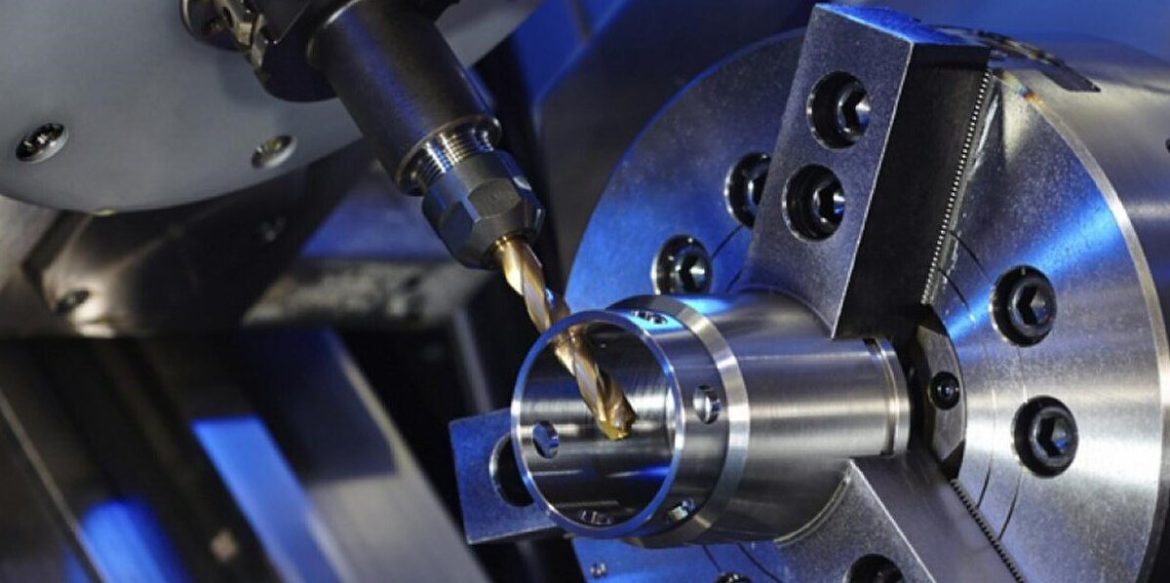

Mining drilling bits are integral tools in coal mining operations, offering a range of benefits that make them an indispensable choice. If you’ve ever wondered why these pieces of technology are so crucial, read on. This article explores the benefits of mining drilling bits, their contribution to safety and efficiency, and their economic implications.

Benefits of Mining Drilling Bits

Mining drilling bits, as their name implies, are used to drill into the earth to extract coal—a resource that continues to play a substantial role in our global energy production. These specialized tools bring several advantages to the table that are vital in the coal mining industry.

Increased Drilling Speed: One of the primary benefits of mining drilling bits is their ability to significantly enhance drilling speed. Thanks to advanced materials and cutting-edge designs, these tools can penetrate coal seams much faster than traditional methods. This rapid drilling capability translates into a quicker extraction process and higher productivity levels.

Improved Accuracy: Mining drilling bits also boast excellent accuracy. They’re designed to drill into specific areas without straying off course, ensuring that the mining process is targeted and efficient. This precision also reduces the amount of waste produced, contributing to a more sustainable operation.

Reduced Downtime: The robust construction of mining drilling bits makes them highly durable. They can withstand harsh conditions and extensive use without breaking or wearing out quickly. Consequently, the downtime associated with replacing or repairing these tools is significantly minimized, promoting continuous operations and maximizing productivity.

Enhanced Safety and Efficiency

Besides their practical benefits, mining drilling bits also play a pivotal role in promoting safety and efficiency within coal mining operations.

Firstly, the precision of these tools helps minimize the risks of unforeseen accidents that may occur due to drilling into the wrong areas or causing unnecessary collapses. Mining drilling bits provide a reliable and predictable drilling pattern, making the entire process safer for workers.

Moreover, by minimizing waste and maximizing resource extraction, these tools contribute significantly to the operation’s environmental efficiency. By extracting more coal per drill and reducing the need for excessive drilling, they help to decrease the overall environmental impact of mining operations.

Economic Considerations

While the initial cost of mining drilling bits may be higher than traditional tools, their advantages over the long term make them an economically sound choice. The increased speed and efficiency they offer lead to more coal being extracted in less time, thus increasing revenue.

Also, their durability means fewer replacements and repairs, resulting in significant savings in maintenance costs. Considering these factors, investing in mining drilling bits can yield substantial financial benefits for mining companies, offsetting the initial expenditure and providing considerable returns over time.

Conclusion

In conclusion, mining drilling bits are not just tools—they are key contributors to successful and sustainable coal mining operations. They boost drilling speed, improve accuracy, and reduce downtime, all while promoting safety and environmental efficiency. Moreover, despite their initial costs, they prove economically viable in the long run due to increased productivity and reduced maintenance requirements. Hence, choosing mining drilling bits is an informed decision that brings significant advantages to any coal mining operation.