LED, like other electrical components, creates heat and causes the temperature to rise during usage or operation. The LED lamp will burn out prematurely thanks to excessive temperatures. That’s why you shouldn’t disregard the thermal dissipation issue.

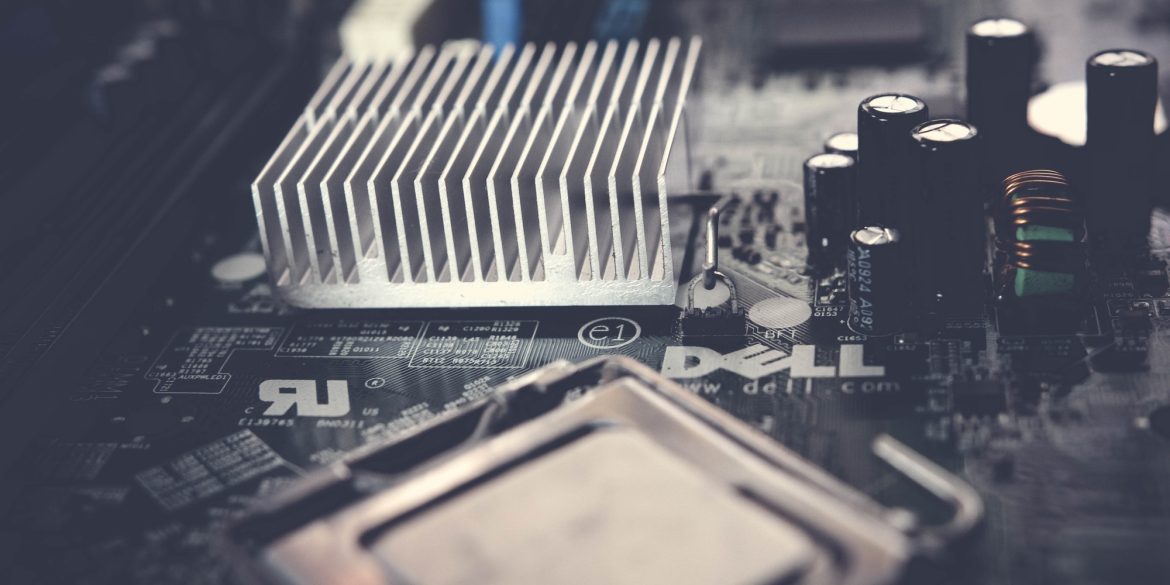

As a result, the LED light must have a heat sink. Different heat sinks, made of various materials, such as aluminum alloy, cast iron, steel, copper, and so on, are available on the market. However, why do LED lights use aluminum extrusion heat dissipation?

In the manufacture of LED lights, aluminum alloy seems to be the superior heat conduction material. Because aluminum alloy has a high heat dispersion coefficient, the price of aluminum LED heat sinks is quite low.

It has strong thermal properties, which can aid in the heat dissipation of LED lights. Furthermore, the aluminum alloy material is lightweight, making it easy to install and move.

LED Junction temperatures have to be kept in check: But why?

It is critical to remove heat from high-power LEDs using effective thermal management. Without proper heat sinking, the LED’s junction (inner) temperature increases, causing the LED’s performance to deteriorate.

The highest permissible Circuit Temperature for High Power LEDs is 125 °C for a short period, 110 °C for a long duration, and 80 °C for Low Wattage LEDs.

The circuit temperature rises while the forward voltage and lumen output of an LED drop. Not only does this reduce the light and performance of your LED, but it also affects the total lifetime of the lamp.

LEDs rarely cause major damage. However, a few may, particularly if they are overheated. But in most cases, the lumen output of the LED decreases over time. Higher junction temperatures accelerate the LED degradation.

How is an extruded aluminum heatsink made?

Cool forge is a method in which metal is squeezed in a mold to adopt the shape of its container. This procedure is carried out at room temperature. This is why it is referred to as cold forging. In terms of heat conductivity, mechanical durability, surface quality, and production cost, cold forging is unrivaled. A cold forging heat sink can outperform a flat cast heat sink by up to 80% in terms of thermal performance.

Another manufacturing method is Extrusion. In that method, the metal material is formed by pressing it through a hole. Shaped steel may be cut to the necessary length. Based on the requirements and techniques, various heat sinks can be created. The extruded aluminum technology provides superior cooling performance to casting.

The stamp is a cool shaping technique used to make metal sheet components. To enhance surface area and refrigerant effectiveness, the metal sheet is chopped, rolled, pulled, and twisted into various forms. All of these methods are used to manufacture and install cooling fins. Stamped heat absorbers can have a variety of attachment ways for specific components. The most significant benefit of stamping heat sinks is their reasonably cheap price due to the simplicity of process automation.